Embedded channel steel assembly

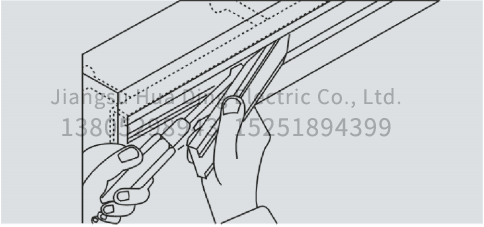

Polyethylene filled: can be directly by hand or use appropriate

tools, such as a screwdriver (screwdriver) will be filled out.

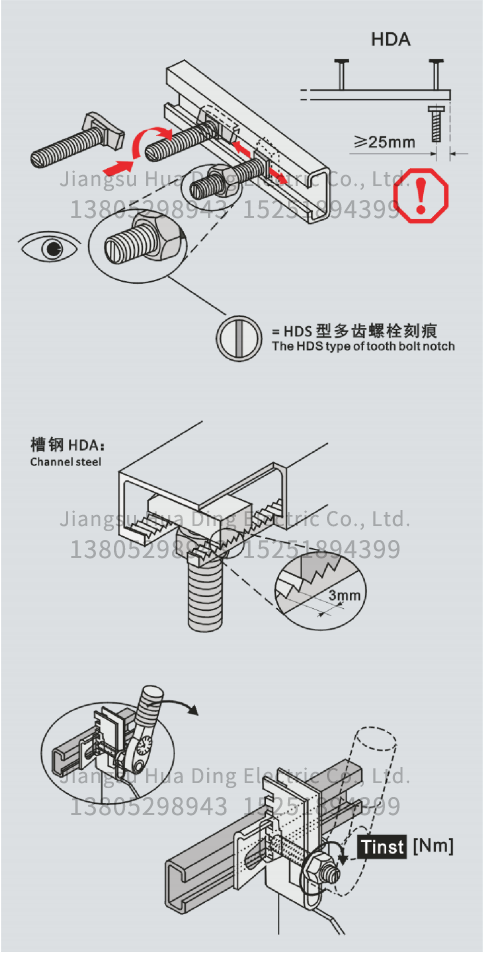

1. Reliable channel of assembly

T bolt can be in any place through the openings into the channel, after 90 °Ctighten nut rotate positioning. Note: bolt is installed in the end the anchor nail (distance channel steel end of 25mm) or the outside.

2. Correction of bolt

Inscribed at the end of the T bolt positioning with Nick: after the bolt into the channel steel, its direction is correct or not can be determine daccording to the direction of the notch, Nick must with longitudinal vertical channel.

3. But regulatory

Toothed channel steel can be through the meshing teeth, the longitudinal load transferring channel, to prevent slipping of the point.

4. Fixed

The ends of the bol t head must and channel steel of bilateral against,then use the torque wrench to tighten.

According to this section, the design of bearing capacity is given in the table values F . Rd

Here the "design value" is based on the current standards of safety standards and the latest, not to be confused with the "permitted" before.

According to the new standard (e.g., EC2, DIN 1045-1, EC3, DIN 18800-1), external load (load) multip lied by ga mma M loads subentry safety system, it is concluded that the design of the corresponding value d respectively.